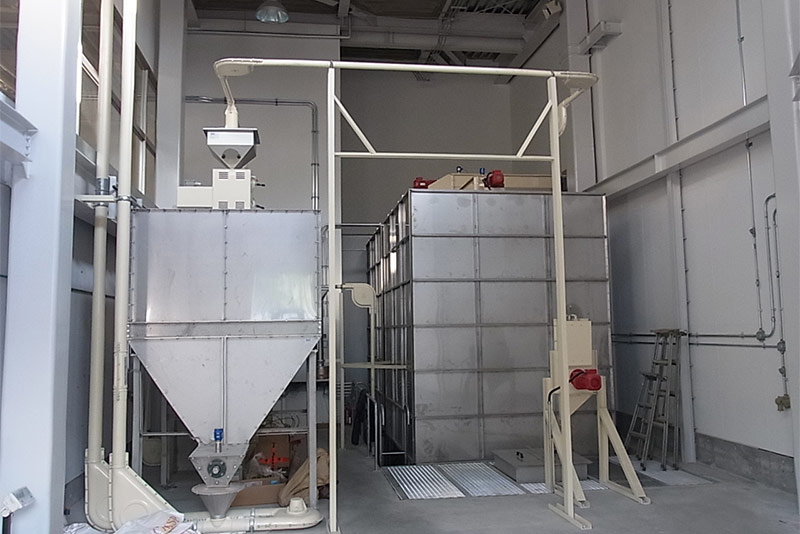

Perfectly milled malt is the base for a efficient high quality mash. We offer a different sizes from small hand mills, standing mills up to fully automized industrial scale mills connected to malt silo and the mash kettle via conveyer belts.

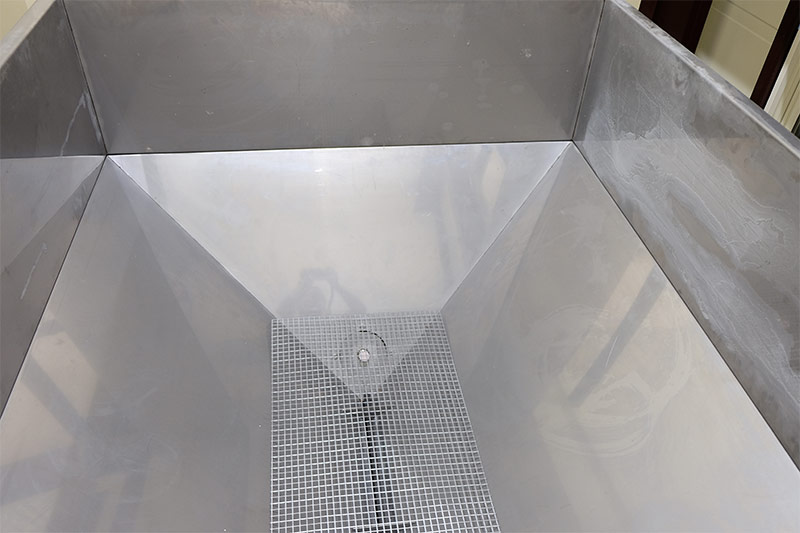

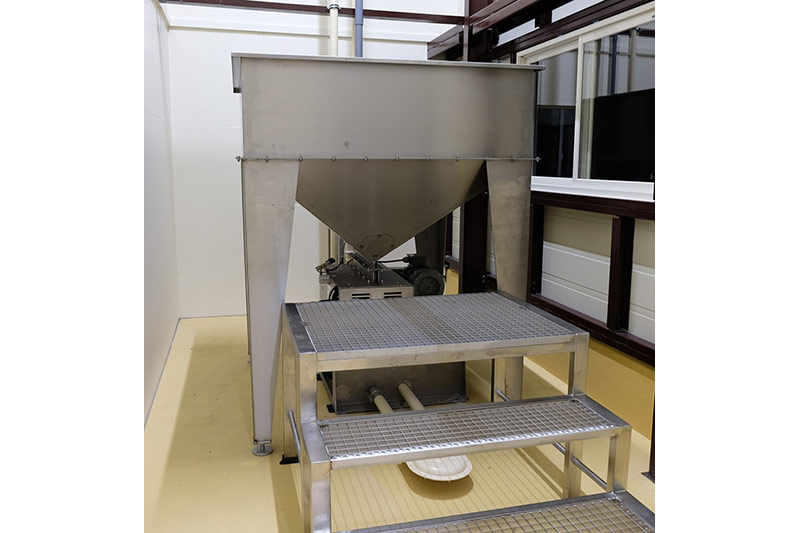

All material in contact with the grains is approved by Japanese food production and sanitary regulations using stainless steel or carbon-steel only. Our mills can be customized as 2, 4 or 6 roller mills according to your production requirements. Hourly capacities can also be scaled respectively.

We can also supply grist cases, malt silos and conveyer belt systems to directly connect your raw material storage and malt mill with the brewhouse.