For more than 10 years BET has successfully built and installed beverage production equipment of all kind and sizes in Japan. A decade of experience gives us the unique ability to fully understand legal, economically and environmental challenges for our clients in Japan. We put this knowledge to work to make each project a success for our clients.

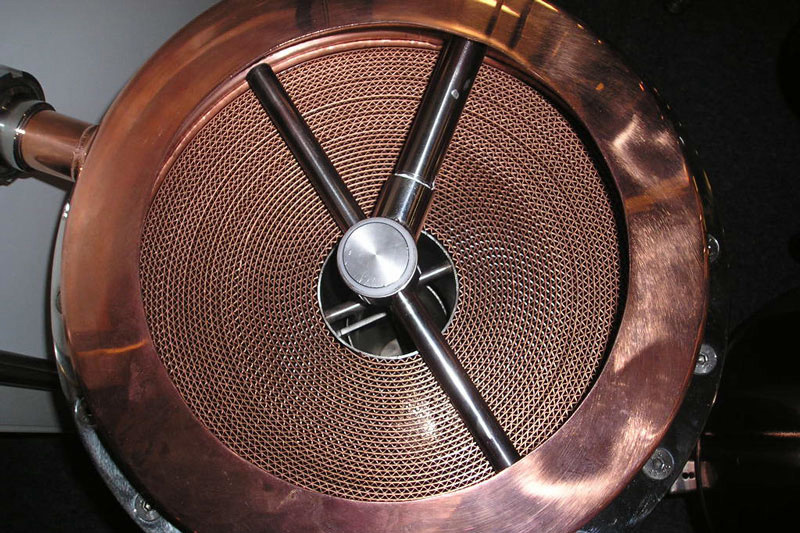

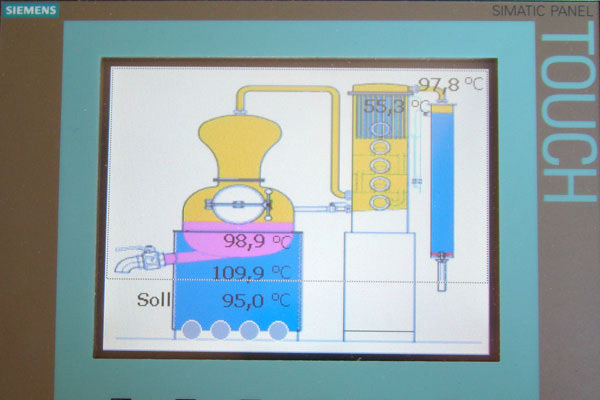

All our distilleries are hand crafted by Arnold Holstein in Germany to your individual requirements. Manufacturing distilleries since 1958 Arnold Holstein combines longstanding experience with state-of-the-art development and engineering technologies guarantee innovative and outstanding solutions.

We offer equipment for batch processing with filling capacities from 5 to 10000 l as well as continuous processing equipment with capacities of up to 5000 l per hour. Our units produce flavor-rich premium products at high productivity rates and with easy handling. The product variety enabled by our equipment knows no limits. Regardless of whether our technology is used for producing premium fruit distillates, whiskey, vodka, grappa, gin, tequila or aquavit – all Holstein units share two things in common: a comprehensive, high quality standard and reliable distillation technology.

All our brewing systems can be equipped with raw material storage, distillate tanks, CIP systems and bottle filling units that fit size and production requirements.